- Home

- About

-

Service

-

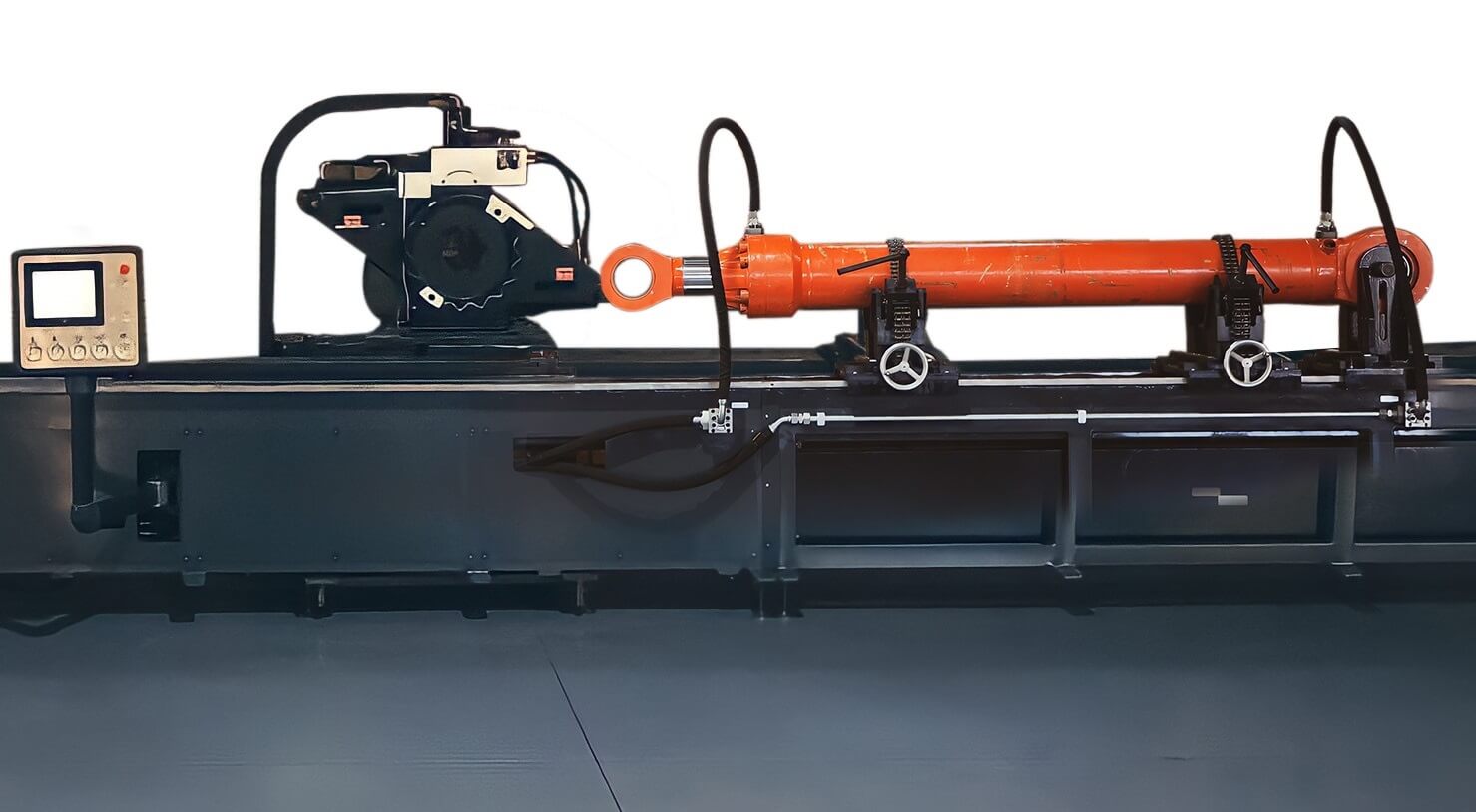

Cylinders & Struts Repairs

Cylinder tube Honing & Rod polish for Re-useability

-

Pumps & Motors

Genuine components replacements at competitive prices.

-

Seals

we provide genuine and after-market OEM seals.

-

Specialised Welding

MIG welding (Metal Inert Gas).Wire. Mild steel, stainless & Hard facing.

-

Line Boring & Bore Welding

Excavator Buckets up to 40m3H-Frames

-

Bucket Repair & Manufacturing

Replace worn lips & wings and structural components

-

Hose & Fittings

We have over 2 decades experience to cut and crimp hoses

-

Drawing Department

We provide accurate 3D measurements of physical objects.

-

Control Valves & Cartridges

Rebuild & Repair Hydraulic valve banks & supply control valves

-

Dump Truck Body

we improve the structural integrity of the body.

-

- Industries

- Join us

- Contact